BRE Burn Hall 3 x 160kW Extraction Fan Control - Case Study

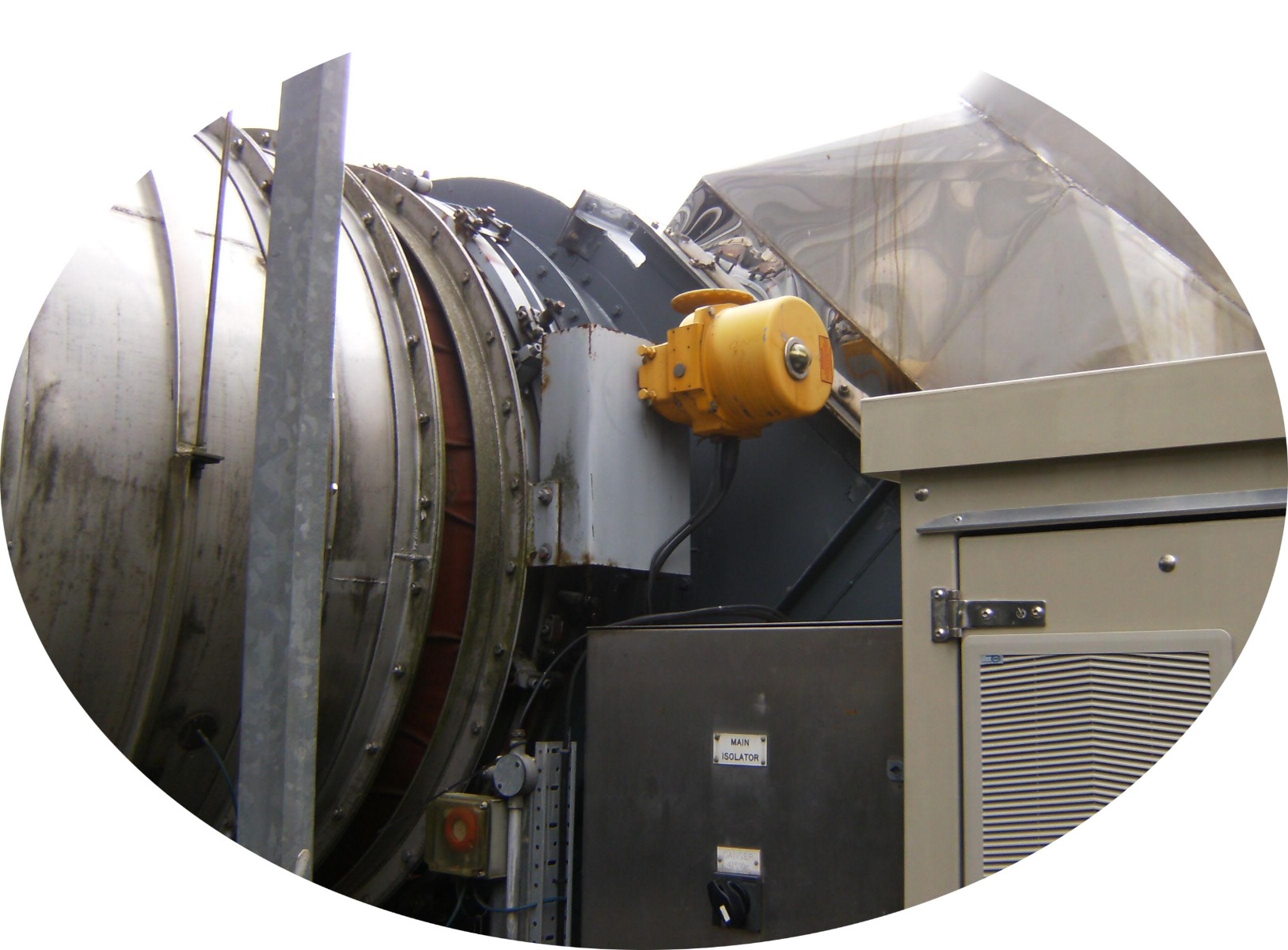

BRE, based in Watford near London, UK operates the largest ‘burn hall’ in Europe. The burn hall is used to carry out flammability testing on various domestic, commercial and industrial products. BRE previously used three 185kW two-speed AC induction motors controlled by star-delta starters to drive large fans to extract fumes from the burn hall after product testing had been undertaken. As the extract fans were being run at full speed the airflow was controlled by three iris air flow valves.

These valves constrict air flow from the fans as required without reducing the energy required to run the fan motors, a highly inefficient system that wasted significant energy. BRE approached Invertek Sales Partner, Motor Control Warehouse, with a view to replacing their star-delta starter system with a variable speed drive (VSD) control system. Motor Control Warehouse in conjunction with BRE, have now designed, built and installed a fully automated VSD control system using three Invertek Optidrive HVAC, 160kW, IP55 AC Drives. The drives are housed in purpose-built glass fibre weather resistant enclosures.

The existing two-speed motors have been adapted for inverter control and have been fitted with specially designed output inductors between inverter and motor to reduce the dV/dt (fast rise and fall) of the switching edges seen by the motor. The new system was integrated in to BRE’s existing automated extraction control system. With the system's iris valves fully open the airflow can now be controlled more precisely by the speed of the extract fans. The speed of the fans has been significantly reduced. This greatly reduces energy usage and gives a short payback period for the upgrade. Kes beech, Technical Manager at Invertek Drives confirms: “Full payback on installation of Optidrive HVAC is usually achieved within 12 months based on current energy costs in this type of application.

In addition, Optidrive HVAC allows fans to run for less time and at lower speeds, greatly reducing maintenance costs and acoustic noise generated by the fans. Kes concludes: “Automated control of fan airflow also eliminates the need for valve adjustments, again reducing maintenance costs. This all combines to provide an overwhelming argument in favour of using Optidrive HVAC for energy efficient fan control. The system was designed, built, installed and commissioned by the team at Motor Control Warehouse.

space

Thanks for reading our case study, if you would like more information please don't hesitate to call us on +44 (0)1686 688948 or visit our contact us page